A really bad point of the XRV 650 is the air intake: It is very low and closed to the rear tyre and as it is impossible to obtain a perfect sealed system between the rileft fairing, the rear mudguard and the frame, dust and mud will always easily reach the air intake and the filter will get dirt easily.

I knew that before buying the motorbike. The original air filter is the best one for the motorbike (regarding filtering and jetting), but sadly it cannot be washed because it is made of paper, the only way is to use air pressure from the inside toward the outside. The exhaust system can be used for this, but it is not as effective as an air compressor gun (anyway the filter won't be new).

A washable K&N filter can be used, but it is not filtering as good as the original one (The engine runs a little bit leaner with K&N filter), so I didn't wanted to use it, because right now my engine is eating 0,5 liter of oil every 10'000 km, which is nothing.

During the trip I used a filter skin, which allows less dirt to reach the filter (the filter skin was a woman PA collant), but it was making the engine running richer.

So I started gathering informations because I wanted to find a solution to this problem, so that the XRV 650 would have been the perfect bike for travelling.

I've look on the internet and I've found that the RD04 Marathon had an air intake of the tank.

I've written to the owner of the website for gathering more informations after seeing this picture of a German guy that was building a Marathon replica:

Tim's marathon replica. Work still in progress?

He answered me very fastly and he sent me two more picture of the snorkel itself.

Tim's marathon replica. Work still in progress?

Very nice snorkel, but I don't like the fact that is made of aluminium, fiberglass would have been cheaper and more lightweight!

Roberto Boano was a pilot that raced the Dakar many times with XRV Marathon series, including a RD04. Right now he is realizing special parts for a lot of Honda Twins bikes and many other models. (

http://boano.com/ ). He has special parts for the XRV 650 such as the bigger marathon style tank and the marathon style rear tank (including the shorter seat with place for the transponder). No clue about the air intake over the tank. So I wrote him an e-mail. He answered me very quickly, but sadly he is just making this modification for marathon bikes, this means:

- *Modify the original airbox for the new air intake and for allowing the use of longer air filter

- *Upper air intake / snorkel

- New seat

- Longer air filter

- Front bigger tank

- Modify the left rear fairing

- New jetting

All together it is costing around 2000 € + VAT (22%!), I've marked with a * the modification that are relevant for me, but they are costing 650 € + VAT, so it was to much for me. He suggested me to use a longer foam air filter with a reduction after it, in order to use the original jetting but having a bigger filtrating surface, would have reduced the maintenance intervals and moreover the foam airfilter is washable. But this was not a good solution for me, because he told me that it has to be cleaned after every day ride if in dusty riding conditions.

Meanwhile I had opened a Thread on the Italian Africatwin club:

and on the xrv community:

I don't like forums, because they are always full "famous" people that are like a God on the forum, and whatever they say, it is true. It happened on the Italian one, I was told it is impossible to modify the air intake of the XRV 650 without changing the jetting, and a lot of people tried to take the air from the front of the bike or more under the seat with a longer air intake, but the bike was running rich after these tries (Of course, if you increase the length of the air intake, you increase its resistance and so "less" air gets into the airbox). But anyway forums are very good for gathering informations.

A guy on the Italian forum did an amazing modification: He adapted the RD07 air filter to the RD03, he had to cut the original tank (after the work the bike had around 17 liters of fuel). Nice work, that could be a very good solution, moreover the place for the air conduct under the tank could have been used for holding more fuel and the same for the place where the original airbox was, so that the fuel quantity of the bike was still the same.

But sadly I can't weld, so it was a no go for me, but I think that this solution is way much better than the snorkel, has it lowers the center of gravity of the bike too.

I've written to Africanqueens.de as well, because they have something about a modified air intake for the RD03 in their onlineshop , but they've never replied me back.

So I decided to do everything by myself. I'd like to thank Simone Gervasoni for the hints on how to do the snorkel. I've done some rough calculations of the original air intake snorkel, in order to have a rough dimension for the cross section of the one over the tank. I ended up having a 120 x 20 mm^2 cross section in order to have a lower air resistance, so that I would have been able to compensate it by inserting a low density foam in the snorkel.

So I've started building it. I did directly the mold on the tank, I covered it with 2 layers of cellophan because Simone told me that almost nothing sticks to it, that's true. The first error was that the resin slightly diffuse through cellophan, so a little bit reached the tank and the resin gest warm during the chemical solidifcation process, this damaged the original decals on the tank. Not a big deal for me. In order to form the snorkel, I've used PEEK foam covered with cellophan.

Ready for closing the snorkel.

Waiting for the fiber to solidifcate.

The top part is done.

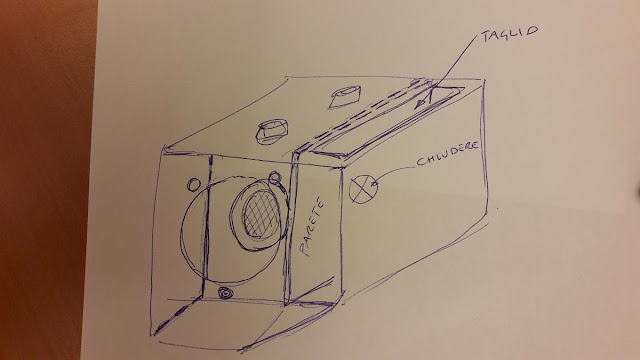

Meanwhile I've modified the airbox, I had to build an internal separation and close the original air intake. The following image was drawn by a user on the Italian Africa twin club forum. Many thanks again mate!

How the original airbox has to be modified for the higher air intake.

Almost finished snorkel.

There were some leaks on the snorkel as fiberglass is not 100% sealed. But I decided to try it in order to see if the bike was lean. That was the case, so I decided to finish it.

I used some fiberglass refinish and then and to build the small border in order to seal the snorkel on the airbox (I've putted some neoprene on the airbox in order to ensure a perfect sealed system).

The connection between the snorke and the airbox.

Then I've painted the snorkel and I had a test ride in order to determin the length of the foam. I started with a 150 mm long foam and at the end I had the perfect jetting with a 20 mm long piece of foam. The seat had to be modified aswell, but that was an easy job.

Next step will be trying a PA collant on the foam, in order to have a pre filtering element that can be easily washed.

The bike has been tested with K&N filter (with the new snorkel there is no risk that a lot of dust will reach it) and Arrow Paris Dakar muffler. The jetting doesn't need any adjustment yet, but I've tested the bike just with an ambient temperature of 12° C.

The three screws have just the purpose to aboid the foam to be sucked into the snorkel.

That's all folks!

UPDATE 25.05.2017

Last week I've been able to ride the motorbike at more than 2000 meters over the sea level: jetting is fine as it was before the modification. At some rpm there are some small fluctuactions of power, probably due to a formation of turbulences into the channel: there is no internal smooth layer, so it is very rough, with spots of fiberglass obstructing it. But the motorbike can be ridden very well anyway in any condition so far (from mud muletracks in first gear to very high mountain pass in fifth gear at 100 km/h).

UPDATE 12.07.2017

I was able to ride in some very hard conditions like deep water, tough mud and higher altitudes (Almost up to 3000 masl). The beast never had a problem. When I removed the left hand rear side cover it was clear that the filter would have suffered a lot from mud as the plate closing the original air intake was still completely covered in mud.

Then after around 10000 km of test, I've removed the seat and the air intake. Everything is still in perfect shape. This is really a modification that I suggest to do if you want to ride the world with an XRV 650.